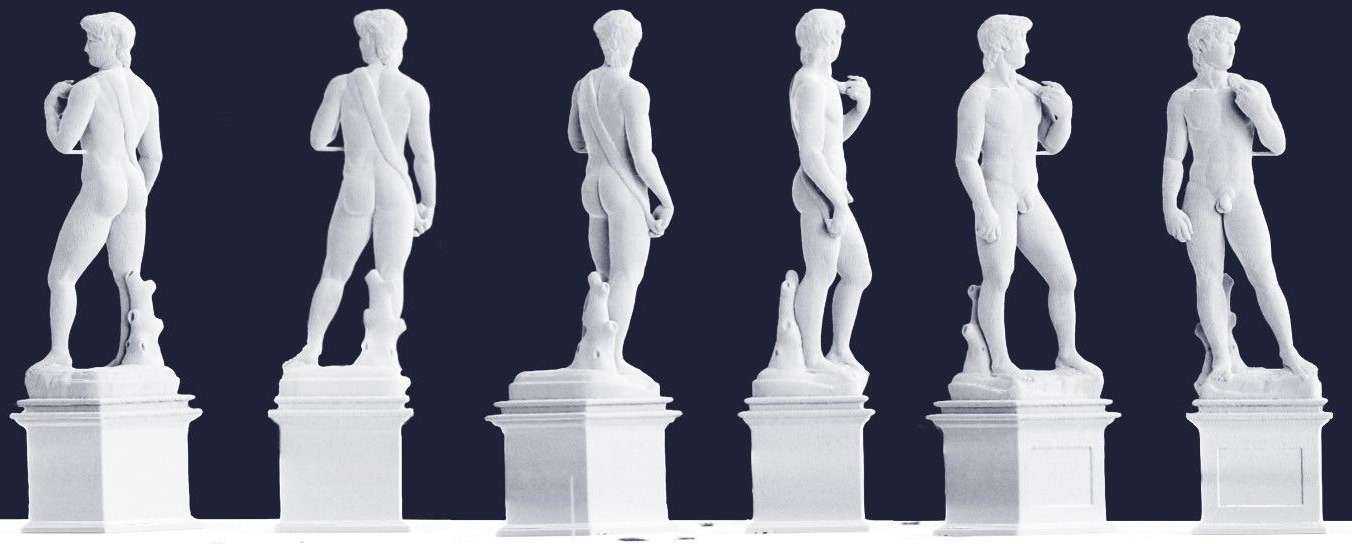

3D printing has proven itself useful in so many industries that it’s no longer necessary to show off, but some people just can’t help themselves. Case in point: this millimeter-tall rendition of Michaelangelo’s famous “David” printed with copper using a newly developed technique.

The aptly named “Tiny David” was created by Exaddon[1], a spin-off company from another spin-off company, Cytosurge, spun off from Swiss research university ETH Zurich. It’s only a fraction of a millimeter wide and weighs two micrograms.

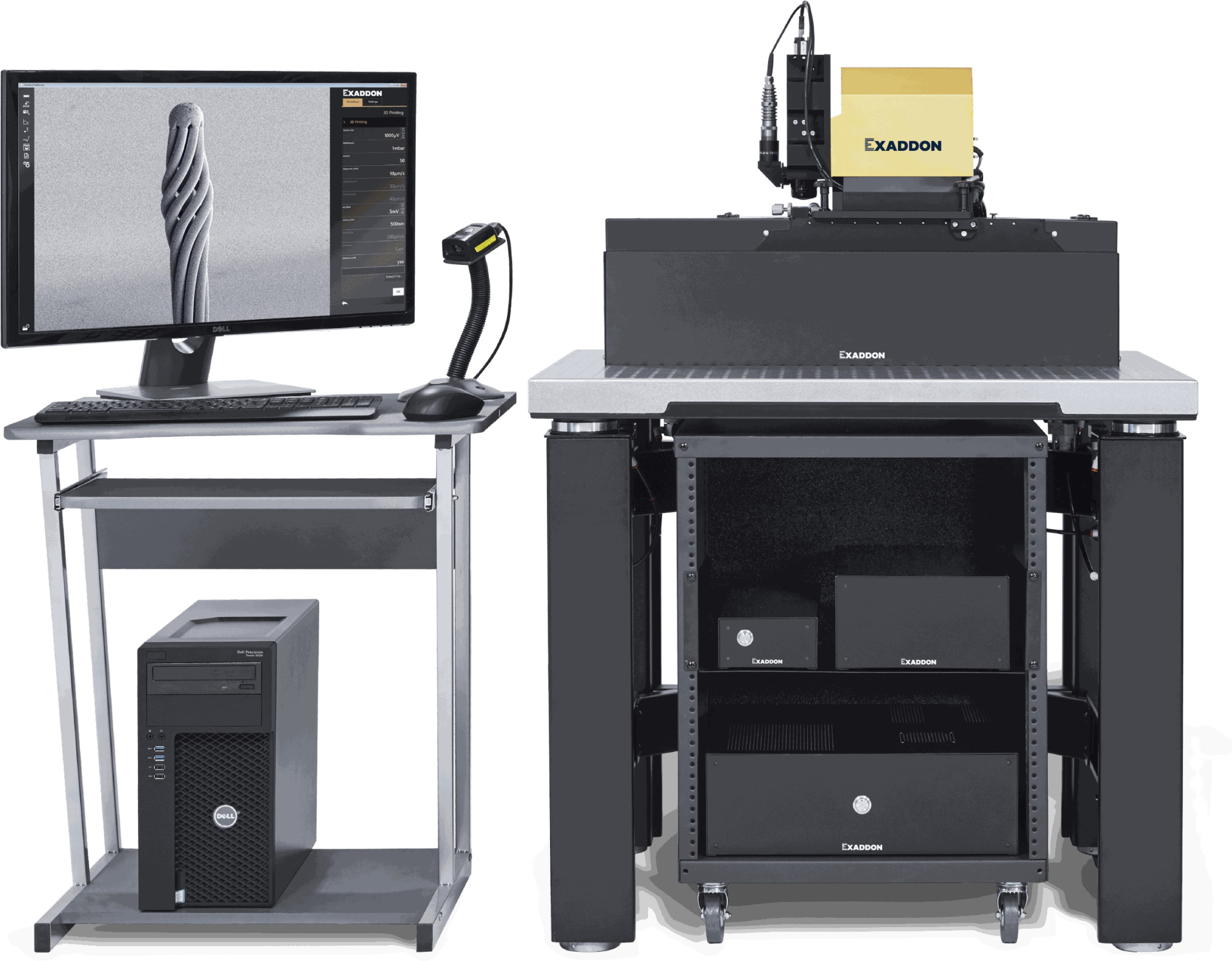

It was created using Exaddon’s “CERES” 3D printer, which lays down a stream of ionized liquid copper[2] at a rate of as little as femtoliters per second, forming a rigid structure with features as small as a micrometer across. The Tiny David took about 12 hours to print, though something a little simpler in structure could probably be done much quicker.

As it is, the level of detail is pretty amazing. Although obviously you can’t get recreate every nuance of Michaelangelo’s masterpiece, even small textures like the hair and muscle tone are reproduced quite well. No finishing buff or support struts required.

Of course we can create much smaller structures at the nanometer level with advanced lithography techniques, but that’s a complex, sensitive process that must be engineered carefully by experts. This printer can take an arbitrary 3D model and spit it out in a few hours, and at room temperature.

The CERES printer.

But the researchers do point out that there is some work involved.

“It is more than just a copy and downsized model of Michelangelo’s David,” said Exaddon’s Giorgio Ercolano in a company blog post. “Our deep understanding of the printing process has led to a new...