A project to 3D-print bulky components in space rather than bring them up there has collected a $73.7 million contract[1] from NASA to demonstrate the technique in space. Archinaut[2], a mission now several years in development from Made In Space, could launch as soon as 2022.

The problem at hand is this: If you want a spacecraft to have solar arrays 60 feet long, you need to bring 60 feet of structure for those arrays to attach to — they can’t just flap around like ribbons. But where do you stash a 60-foot pole, or two 30-foot ones, or even 10 six-foot ones when you only have a few cubic feet of space to put them in? It gets real complicated real fast to take items with even a single large dimension into space.

Archinaut’s solution is simple. Why not just take the material for that long component into space and print it out on the spot? There’s no more compact way to keep the material than as a brick of solid matter.

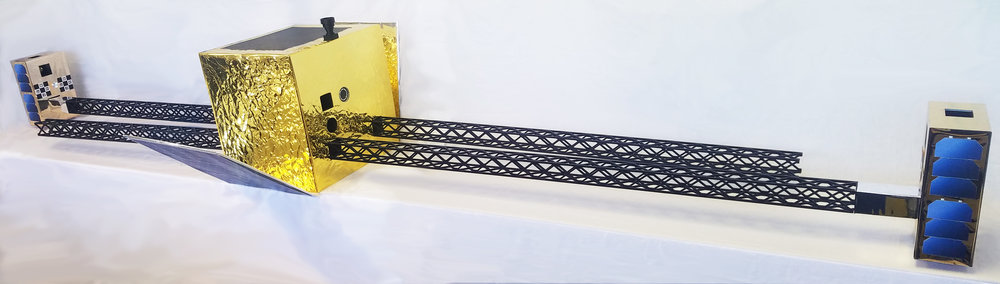

Naturally this extends (so to speak) to more than simply rods and poles — sheets of large materials for things like light sails, complex interlocking structures on which other components could be mounted… there are plenty of things too big to take into space in one piece, but which could be made of smaller ones if necessary. Here’s one made for attaching instruments at a large fixed distance from a central craft:

Made in Space already has contracts in place with NASA, and has demonstrated 3D printing of parts aboard the International Space Station. It has also shown that it can print stuff in an artificial vacuum[3] more or less equivalent to...

Made in Space already has contracts in place with NASA, and has demonstrated 3D printing of parts aboard the International Space Station. It has also shown that it can print stuff in an artificial vacuum[3] more or less equivalent to...